Exchange of knowledge between Siemens, Quinaptis and Thomas More Hogeschool produces fruitful cross-fertilization

The Dutch version of this article can be read on the Siemens website.

Click here to download the French version (PDF) and here for the German version (PDF).

See also belganews.be, metaalvak.be, invlaanderen.be, Productivity.be, Engineering.net,

Industrial Automation, Made in Antwerpen, NNieuws, Flows, Warehouse Totaal,

Value Chain, Transport Media, Logistiek.be, Technologie & Industrie, Automation Magazine.

Industry 4.0 to the max

Programmable controllers (PLCs) are often used to operate automatic cranes in a warehouse. In that same warehouse, inventories can be managed, and goods flow planned using SAP EWM software. Siemens, Quinaptis and Thomas More College in Geel have joined forces to link up PLCs and SAP EWM safely, efficiently and accurately. Their solution is groundbreaking. The proof that one plus one really can make three.

The optimum use of a continuous stream of data from disparate sources can ensure the optimum working of a warehouse. There’s a problem though: the world of logistics (managing the warehouse and its inventories using SAP EWM software) and the world of automation (managing the cranes using PLCs) are different. Nevertheless, linking both up can bring about a huge increase in inefficiency. Just think of the preparatory work that cranes could do of their own accord at night to save time during the day.

As an SAP specialist, Quinaptis has long been working on improving the way automated warehouses are run, for example by planning specific tasks and enabling the cranes to carry out specific movements ahead of time. “We’ve long been working on a solution to link up inventory management and process automation and to enable both lots of software to ‘talk’ to each other, primarily via SAP’s Material Flow System (MFS). But as an SAP specialist, we only have limited in-house expertise when it comes to automation. Which was why we called on Siemens, the market leader in PLCs, to bring the two worlds together”, says Dieter Baert, Logistics Consultant SAP at Quinaptis.

Together with An Lietaert, who is an automation specialist at Siemens Belgium, they examined various ways of creating the link between SAP EWM and the PLC. “I suggested doing it on the basis of Virtual Commissioning”, she says. Virtual Commissioning entails subjecting a machine, a system or in this case an automated warehouse to a virtual trial run prior to delivery. A ‘digital twin’ of the system is created, even before commissioning, to uncover and debug any faults. “This digital twin can be produced using the Siemens NX MCD software, in this instance in combination with PLC-SIM advanced software based on a Siemens PLC (SIMATIC S7-1500)”, she explains.

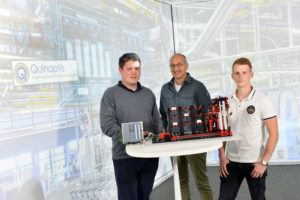

Top-notch project team

Quinaptis and Siemens would thus develop both a real and a virtual version of a warehouse, in which SAP EWM and PLC would communicate and cooperate. No simple task. The two partners turned to Frank Peeters, a professor in process automation at Thomas More College in Geel, where working with PLCs has for many years been an important part of professional training for a bachelor’s degree in electromechanics. He looked for two students who were willing to take on this dual challenge for their bachelor’s examination. “This was no mean feat because the students knew nothing about the NX-MCD software and even less about SAP software. Gillian Stevens and Stef Dierickx took up the gauntlet”, says Frank Peeters.

In February a top-notch project team was put together, consisting of two experts from Quinaptis, two from Siemens and two students. “The knowledge of Siemens PLCs was already in place. First, we had a week’s training on NX-MCD at Siemens. Then Quinaptis provided technical support as regards SAP EWM”, say the students.

Proof of concept

It was decided to develop and test the concept via both HiL (Hardware-in-the-Loop) and SiL (Software-in-the-Loop). In other words, the problem would be approached from both the hardware and the software perspective. But because testing in a real warehouse – the hardware – is difficult to achieve, the students worked with an automated miniature warehouse from Fischer Technik, controlled by a PLC. “That was to serve for the tangible ‘proof of concept’. Alongside this we got to work on NX-MCD software to also create a digital version of it – the ‘digital twin’’”, explains Stef Dierickx.

“First, thanks to the miniature warehouse, we further developed and fine-tuned the communication between the SAP software and the PLC computer. Then we produced the warehouse virtually. That let us uncover and resolve faults much faster. We were also able to simulate faults and so debug them proactively”, adds Gillian Stevens.

The result of this approach was highly successful. It produced a workable proof of concept. “The NX-MCD simulation tool not only lets us verify that the SAP EWM/PLC communication works, but also that the concept is scalable and can be used in a real warehouse, with real cranes”, says Stef Dierickx.

“More than that: the same concept can be used for communication between SAP EWM and PLCs to manage other warehouse devices, such as Automated Guided Vehicles (AGVs) and robots”, adds Dieter Baert.

Cross-fertilization

All three parties are highly satisfied with this successful collaboration.

“We learned a huge amount, as regards both SAP EWM and NX-MCD. We are grateful to Siemens and Quinaptis because they gave us so much freedom – as well as responsibility – in the course of the collaboration”, say the students. Their very strong performance in their bachelor’s examination was rewarded with a 17/20. “This type of collaboration is definitely something that could be repeated”, adds Frank Peeters.

“Approaching a project in terms of software often works much quicker and more efficiently. The process also proved that the exchange of knowledge between parties from different worlds ends up in a fruitful cross-fertilization: in this case, the whole was clearly more than the sum of the parts”, says An Lietaert.

“Thanks to this collaboration Quinaptis gained experience with Virtual Commissioning. But the cross-fertilization was above all important in respect of the PLC and the way it is managed via SAP MFS. In the future that will improve communication between our SAP specialists and PLC experts from Siemens, which will speed up the development of market-ready solutions”, says Dieter Baert in conclusion.

Quinaptis bv

Quinaptis bv